Fields of application

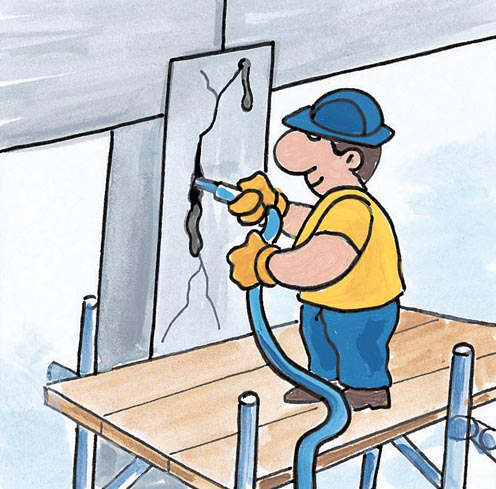

Reinforcing and filling injections of cracks in concrete, stone, brick, mixed works etc. Anchor, bonding and attachment of connectors, plates etc. Structural reinforcement and small volume rebuilding (only horizontal) in general. Reinforcement of porous construction materials such as wood, natural stone, bricks etc.

Allowed supports

Plasters

Concrete

Cement-based or lime-based mortars

Prefabricated concrete

Wood

Bricks

Tuff

Mixed walls (bricks and stones)

Stone walls

Floor screed

Rock walls

Preparation of supports

The surfaces of application will be seasoned and dry (residual humidity measured at a depth of 4 cm, should not be greater than 4 % ), free from dust, grease, soiling, crumbling and non-adhering parts.

Mode of use

Make sure that the environment is well ventilated and wear the personal protective equipment mentioned in the safety data sheet. Add component B to component A taking care to remove all the material from the packaging, mix thoroughly with a mixer at a low number of revolutions, until a perfectly homogeneous mixture is obtained; add the required load amount (component C) continue to mix until a perfectly homogeneous lump-free mixture is obtained. Lay the material using the techniques specific to the type of intervention: injection, pouring, brushing, etc..

Do not apply on wet or pulverised media. Non-conformities of the support can have unpleasant drawbacks: detachments, large bubbles, etc. Apply only in the intended thermal intervention (+8/+35 °C).

Use the product immediately after mixing and mix only the amount of product intended for immediate use.

Syntech IC 55 is a product based on fluid epoxy resins. It may cause variations in the colour of the product on which it is applied, both wood and stone material. For this reason it is recommended to carry out preliminary tests.

Application methods

Pour out

Injection

Brush

Paint roller

Technical specifications

Ratio of catalysis

in peso

A : B = 100 : 50 %

Resistance to the extraction of the steel bars with improved adhesion

UNI EN 1881

0.1 mm

Touch hardening at 20°C

a 20°C

6-8 h

Injectability in wet sand column

EN 1771

190 s

Compressive strength

UNI EN 12190

> 70 N/mm²

Glass transition temperature

UNI EN 12614

50 °C

Static elastic modulus

ISO 178

3000 N/mm²

Complete hardening at 20°C

a 20°C

7 day

Injectability in dry sand columns

EN 1771

190 s

Consumption

Approximately 1.1 kg of SYNTECH IC55 for each cubic decimetre of volume to be filled.

Packaging and dimensions

Can 1 kg [A]

Can 0.5 kg [B]

Kit: 1 Can 1 kg [A] + 1 Can 0.5 kg [B]

Can 5 kg [A]

Can 2.5 kg [B]

Kit: 1 Can 5 kg [A] + 1 Can 2.5 kg [B]

Storage and conservation

Protect from freezing.

Warnings

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.